PUF/PIR Insulation Products & Services

PUF/PIR Insulation Products & Services

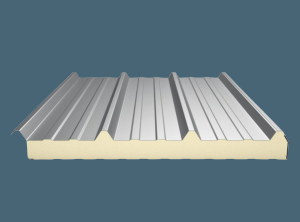

Polyurethane (PUF) A polyurethane is typically produced by reacting an isocyanate with a polyol. Since polyurethane contains two types of monomers, which polymerize one after the other, they are classed as alternating copolymers. Both the isocyanates and polyols used to make a polyurethane contain two or more functional groups per molecule. This creates a rigid foam that has outstanding insulation properties and is suitable for application at a temperature range between -180 C to +110°C.

Polyisocyanurate (PIR) A thermoset plastic typically produced as a foam and used as rigid thermal insulation. The starting materials are similar to those used in polyurethane (PUR) except that the proportion of methylene diphenyl diisocyanate (MDI) is higher and a polyester-derived polyol is used in the reaction instead of a polyether polyol. The resulting chemical structure is significantly different, with the isocyanate groups on the MDI trimerizing to form isocyanate groups which the polyols link together, giving a complex polymeric structure, Which creates rigid foam slabs, Pipe sections, and Pipe supports Are suitable to withstand the temperature ranging between(-) 200°C to +150°C. It has low thermal conductivity and high resistance properties. It is one of the most suitable insulation materials for cryogenic applications.

Key Features

1. Easy to install

2. Light Weight

3. Low maintenance

4. Waterproof

5. Excellent thermal insulation properties

Interested? Take the next step now.

Our team is here to help you with your requirements.

Request a quote now or get more info by downloading the brochure.